ROPES

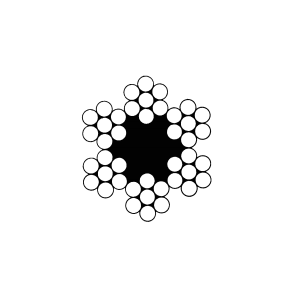

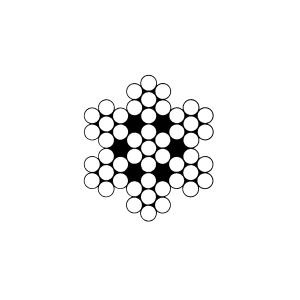

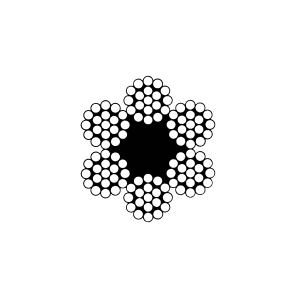

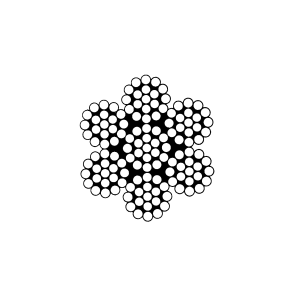

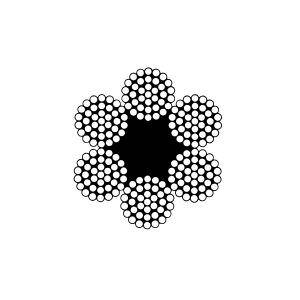

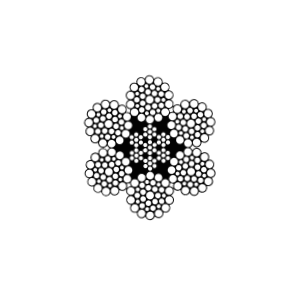

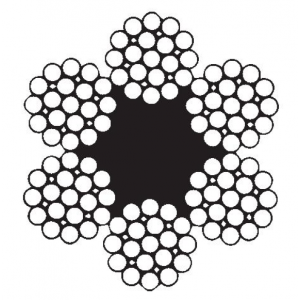

Standard lifting ropes are sets of wires helically wound around a central wire in one or more layers, forming strands. These strands are in turn wound around a core or a web to form multi-strand ropes. Thus, there are several standard rope types depending on the number of strands and wires and the core chosen.

On our website, we offer standard ropes in line with 6 and 7 strands with either a textile or a metal core. These ropes are suitable for all applications (cranes, hoists, gantries, draping, forestry, architecture and others).

The number of strands and wires defines the flexibility of the rope, the more wires the rope has, the more flexible it is. However, the diameter of the wire can have an impact as the larger the diameter the stiffer the hoisting rope.

How to choose a standard rope ?

To choose your standard rope, you need to know several things

The type of use you want to make of it: small diameter standard ropes will be used mainly for architecture and large diameter standard ropes for zip lines or cranes. Some standard lifting ropes are used for hoists, gantries or winches for hauling or skidding.

The weight of the load to be lifted: the larger the diameter and thickness of the rope, the greater the breaking strength of the standard lifting rope.

The movement of the load, whether it is free or guided, must then be known in order to adapt the type of standard rope

The winding direction of the rope: To find out the winding direction of your rope, stand next to the drum where the rope is attached, then wind the rope onto the drum while checking the direction of rotation. If the drum rotates clockwise, the rope is crossed to the right, if not, the rope is crossed to the left.

Finally, you should always be aware of the environment in which your standard cable will be used to ensure that you have chosen the right material that will be resistant to moisture or high temperatures.

We offer bare hoist ropes for sale, without lifting accessories. If you would like to add cable protection or accessories, please contact our customer service department. Standard ropes are sold by the metre but can be supplied in 25m and 50m reels or in any length you require. In our lifting and handling workshops we cut and manufacture rope for all lifting operations.

The control of your standard ropes must be done daily. The AFNOR E52-402 standard recommends a daily visual inspection to determine deterioration and deformation. Particular attention should be paid to the attachment points of the ropes. Periodic general inspections can be carried out in our workshops in order to check the safety of the cables. It is impossible to give an exhaustive list of all the mechanical damage that a cable can suffer during its life. When a cable has a birdcage, a crush, a track or an impact, make sure you do not use it any more at the risk of putting yourself in danger. In the event of wire breakage, reduction in cable diameter, corrosion, wear and tear and deformation of the cable, consider returning your standard cable to our workshops.

For more information on standard cables and ropes, please contact our customer service department, they will answer all your questions.