HORIZONTAL LIFELINES

Mobile cranes, ideal for indoor use. The mobile jib crane can lift loads ranging from 150 kg to 500 kg with a radius of action of around two metres. The mobile jib crane can be moved by means of all-terrain wheels, which allow it to move on any type of ground. The most commonly used model is the mobile jib crane with a triangular boom with a hollow profile that adapts to workshop conditions.

Drum cranes are the most common cranes, especially in the industrial sector. This type of crane is designed to move very heavy loads of up to several tonnes. They can be used for both indoor and outdoor applications. The jib crane is fixed with chemical anchors or with anchor rods and concrete blocks. The jib cranes are available with a triangular or inverted jib with a rotation range of 270° to 360° and a reach of up to 9 metres.

The wall-mounted jib cranes are equipped with a triangular or inverted jib, which reduces the headroom. The wall-mounted jib crane has the option of being motorised or manual with a 180° rotation. The wall-mounted jib cranes are suitable for individual use and avoid clutter in the work area. The lifting capacity of this type of jib crane ranges from 150kg to 4 tonnes with a standard reach of up to 8000mm.

To choose the right jib crane for your lifting application, you need to:

Know the environment in which you want to install your jib crane. This will allow you to choose between a fixed jib crane, a mobile jib crane or a wall-mounted jib crane.

Know the load you wish to lift with the crane. The weight will allow you to choose the necessary lifting capacity.

Know the maximum height and reach required to lift the load.

Know the type of jib crane you want : you can choose between an electric jib crane or a manual jib crane.

A design office is at your disposal to meet your lifting needs for your cranes and gantries. The design office will draw up an estimate according to your request. For further information, please contact our customer service.

Horizontal Lifelines : definition

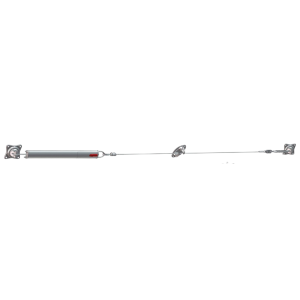

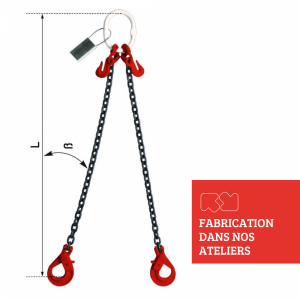

The horizontal lifeline is used to restrain users' falls. It consists of at least two anchorage points, between which a rope, cable, strap or chain is stretched. The horizontal lifeline is usually made up of a cable or a rail. It has a system for adjusting the tension. It also has a shock absorber to limit the impact on the structure, a minimum of two fixed anchors, intermediate pick-up points and angles. This system is a continuous, almost horizontal support with an inclination of less than 15°C.

The lifeline can be adapted to a multitude of configurations. It can be installed on a pitched roof, on a flat roof or on different materials (such as steel, membranes, zinc, copper, concrete, fibre cement). The safety line must be above the user's head and between the anchor points. There are two types of horizontal lifeline: the category B safety lifeline (also called "temporary lifeline"), and the category C lifeline (also called "permanent lifeline").

Different types of Lifelines

There are two types of horizontal lifelines :

The horizontal rope lifeline

The first one is the horizontal rope lifeline, which consists of a rope attached to anchors. Its belay system is extremely flexible. It allows workers to move safely with their PPE.

The horizontal rail lifeline

The second type, the horizontal rail lifeline, is similar in every way to the horizontal rope lifeline, the only difference being that the rope is replaced by a rail.

How to use a horizontal lifelines ?

In order to move safely on a horizontal lifeline, users must regularly attach their personal protective equipment to the cable. Therefore, it is very important that all PPE is checked periodically. In general, horizontal lifelines should be checked at least once every twelve months. However, care should be taken as some PPE needs to be checked more frequently. Checks of such PPE should be carried out by qualified persons who may or may not belong to the establishment. All dates, together with the results, must be recorded in the safety register. Our teams are authorised to carry out the inspection of your lifelines directly on your premises. For more information, please contact our customer service.

How to install a horizontal lifeline ?

The installation of a horizontal lifeline requires precision and expertise. It must be carried out by a professional in order to guarantee total safety. The professional who carries out the installation must take into account the specifications. These specifications define in particular: the working hypotheses, the calculation notes, the characteristics of the equipment, the test reports, the conformity to the standards, the instruction manuals, the list of parts used, the anchoring points chosen, the necessary protection against corrosion, the installation of a detector (or an overload indicator) and the layout plans.

What are the regulations for lifelines ?

Work at height is regulated by Article R4323-61 of the French Labour Code. This article explains the requirements for PPE against falls from a height, in the event that collective or temporary protection is not possible. The French standard EN795 divides the anchorage points into 5 different types. The first is type A or EN795-A. It describes single anchorage points that are anchored to the support. The second is type B (or EN795-B) which corresponds to temporary anchorage points that can easily be removed, as well as those that are simply wedged. The third is Type C (or EN 795-C) which describes lifelines. The fourth is Type D (or EN795-D). It corresponds to rail systems. Finally, the fifth and last anchorage point is Type E (or EN 795-E) which describes temporary systems stabilised by their own weight.

In general, devices A, C and D are supplied with a certificate of conformity which is issued by an approved body.

How do I maintain my horizontal lifeline ?

All installations, technical devices and safety devices in workplaces (whether lifelines or personal protective equipment) undergo regular checks and maintenance at corresponding intervals. Any defects that could affect the health and safety of workers are eliminated as soon as possible.

All lifelines used on construction sites are required to be inspected before being put into service and as often as possible. This is especially true after any modification or replacement of parts, after a failure or when the device has already been used to stop a fall. The device may not be reused without first being examined by the manufacturer.

Levage Manutention, supplier of safety equipment

As a manufacturer and distributor of your lifting and handling products, we are committed to guaranteeing your safety during your operations at height. This is why we have selected a wide range of products from our partners, specialists in their field. We work with Kratos Safety to ensure your safety.

All our products are available for delivery anywhere in France. If you would like more information on our range of safety products, please contact our expert service, they are at your disposal from Monday to Friday between 8am and 5.30pm. Your quotation is free of charge. Finally, if you would like information on the use or safety of our products, a blog is available online.