MAGNETIC CARRIERS

Mobile cranes, ideal for indoor use. The mobile jib crane can lift loads ranging from 150 kg to 500 kg with a radius of action of around two metres. The mobile jib crane can be moved by means of all-terrain wheels, which allow it to move on any type of ground. The most commonly used model is the mobile jib crane with a triangular boom with a hollow profile that adapts to workshop conditions.

Drum cranes are the most common cranes, especially in the industrial sector. This type of crane is designed to move very heavy loads of up to several tonnes. They can be used for both indoor and outdoor applications. The jib crane is fixed with chemical anchors or with anchor rods and concrete blocks. The jib cranes are available with a triangular or inverted jib with a rotation range of 270° to 360° and a reach of up to 9 metres.

The wall-mounted jib cranes are equipped with a triangular or inverted jib, which reduces the headroom. The wall-mounted jib crane has the option of being motorised or manual with a 180° rotation. The wall-mounted jib cranes are suitable for individual use and avoid clutter in the work area. The lifting capacity of this type of jib crane ranges from 150kg to 4 tonnes with a standard reach of up to 8000mm.

To choose the right jib crane for your lifting application, you need to:

Know the environment in which you want to install your jib crane. This will allow you to choose between a fixed jib crane, a mobile jib crane or a wall-mounted jib crane.

Know the load you wish to lift with the crane. The weight will allow you to choose the necessary lifting capacity.

Know the maximum height and reach required to lift the load.

Know the type of jib crane you want : you can choose between an electric jib crane or a manual jib crane.

A design office is at your disposal to meet your lifting needs for your cranes and gantries. The design office will draw up an estimate according to your request. For further information, please contact our customer service.

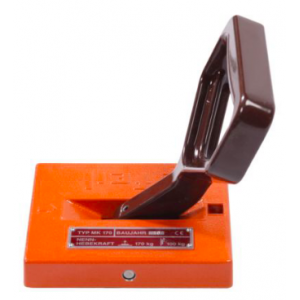

Magnetic carriers or lifting magnets are very powerful, simple and easy to use lifting equipment and handling devices that do not require maintenance. The power is supplied by a switch handle which activates or deactivates the magnet. Our magnetic lifters have a safety system that locks the lever when lifting the part to prevent accidental deactivation.

Magnetic lifters are used in many industrial and metallurgical fields such as foundries, steel mills and the steel and metal trade. The lifting force of the magnetic carrier varies depending on the steel grade, thickness and contact area.

There are two types of operation on the Magnetic Carrier: Operation can be manual or electrically controlled by permanent magnet for horizontal or vertical use for lifting and handling flat and cylindrical parts. The one and only element that can limit the operation of this handling tool is the magnet.

How to choose the magnet for your magnetic lifter ?

In order to choose your magnet properly, there are several selection criteria to consider:

Measure the amount of pure iron in your workpiece to be lifted, as steel does not only have iron in its composition.

Determine the thickness of the part (in mm or cm depending on the part).

Evaluate the roughness and flatness of the part (in mm), the flatter and smoother the part, the easier and more efficient the lifting of the load with the magnetic carrier.

Determine whether or not there are holes or recesses in the part.

The WLL's of magnetic carriers are valid for steels with a low carbon content and low roughness (> 0.1 mm).

For more information on magnetic carriers, please contact our customer service department, they will answer all your questions.