TEXTILE DUNNAGE

Textile lashing definition

Lashing is a device that holds cargo on a transport vehicle without it moving. By means of straps, lashing chains or other accessories, lashing will stabilise the cargo during the entire journey. Textile lashing focuses solely on lashing with the use of textile webbing. This type of lashing is ideal for heavy duty trucks that mainly transport palletized materials. Textile lashing will then be supplemented with accessories such as corner protectors.

What are the characteristics of textile lashing ?

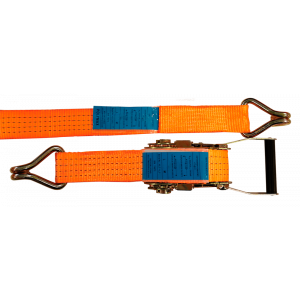

Textile lashing systems consist of a strap, a fastener at one end and a tensioning device at the other end. Thus, these systems are often accompanied by tensioners, which can be ratchet or reverse ratchet, and so-called close or spread fingers. The whole system together will allow you to secure your strap from one point to another. Straps are often made of synthetic fibres or polyester. If you want to use a lashing system, you must ensure that it complies with EN12195-2 or an equivalent standard.

On our website you will find lashing systems at reduced prices, manufactured in our workshops in France. The straps are available in 50mm or 75mm widths with a colour that is different depending on the TMU lashing capacity. Polyester lashing straps have a high resistance to corrosive acids. Default strap lengths are available, for more lengths please consult our customer service.

Each textile strap has an identification label, consisting of two parts, which summarises the main characteristics of the product. On this label you will find the most important characteristics such as the lashing capacity, the length in metres and the year of manufacture. It also contains general characteristics such as the name of the manufacturer, the standard number, the percentage of elongation, the manufacturer's traceability code, the material of which the strap is made and the tensioning force. The label must be present. It can be folded in half, sewn entirely or partially onto the webbing, or protected in a pocket between two layers of webbing fabric.

How to use your textile lashing ?

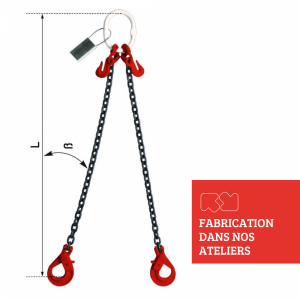

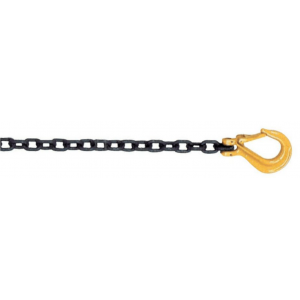

Textile lashing systems should only be used for lashing operations, not for lifting operations. There are different lashing systems (chain lashings or webbing lashings), their use is different and suitable for a situation, this is due to their behaviour and elasticity being different under tension. When operating with webbing it is imperative to ensure maximum tension by manual action on the tensioner.

The maximum lashing capacity is defined on the label on the lashing strap, which can be folded, sewn or protected in a pouch. During the operation, and especially just after starting, it should be checked regularly that the tensioning force is respected. It is not permitted to overload the tension of the straps with any accessory. Also, make sure that the load is stable and that the release of the lashing system will not cause the load to fall. Under no circumstances should the straps be knotted or tensioned in contact with sharp edges or rough surfaces. For this purpose you should use strap protection accessories such as angle irons. The lashing systems should be used in a temperature range of -40°C to +100°C, beyond which they are unusable. It should be checked during operation that there is no change in temperature, in which case this could alter the tensioning force.

Finally, after your operation, your lashings should be stored in a cool, dry place, away from sunlight and chemicals. Regular inspection and maintenance is essential to ensure that they remain in good working order.

How to check your textile lashing ?

Before each use of your textile lashing, a quick visual check should be carried out. Lashing systems cannot be used if they show signs of damage such as tears, cuts, slashes, fibre breaks, heat distortion and missing identification labels. Also, please check the condition of accessories on the lashing system such as turnbuckles or others. These should be free of deformations, cracks, heavy wear and corrosion. Finally, check that there has been no contact with chemicals, in which case your product should be taken out of service.

Levage Manutention creates your textile lashing

At Levage Manutention, we are committed to meeting your needs with tailor-made products at the best possible price. That is why our textile lashing systems are designed in our workshop in Lesquin, France, a few kilometres from Lille. Our seamstresses assemble the accessories and straps to form a unique system that meets the current standards. You can select the lashing that suits you on our website, but you can also contact our customer service department for a tailor-made lashing.

Our website is dedicated to lifting and handling professionals. We manufacture and distribute products for all lifting, lashing and handling operations. On our website, you will find a wide range of products: lifting and handling equipment, slings, lashing chains, webbing slings, safety equipment...

We select premium brands in order to offer you the best products with a certified quality of work. We also offer inspection and repair services for lifting equipment and accessories.

Finally, a blog is available free of charge for all users to answer your questions on the maintenance and use of the products offered.