MANUTENTION

Mobile cranes, ideal for indoor use. The mobile jib crane can lift loads ranging from 150 kg to 500 kg with a radius of action of around two metres. The mobile jib crane can be moved by means of all-terrain wheels, which allow it to move on any type of ground. The most commonly used model is the mobile jib crane with a triangular boom with a hollow profile that adapts to workshop conditions.

Drum cranes are the most common cranes, especially in the industrial sector. This type of crane is designed to move very heavy loads of up to several tonnes. They can be used for both indoor and outdoor applications. The jib crane is fixed with chemical anchors or with anchor rods and concrete blocks. The jib cranes are available with a triangular or inverted jib with a rotation range of 270° to 360° and a reach of up to 9 metres.

The wall-mounted jib cranes are equipped with a triangular or inverted jib, which reduces the headroom. The wall-mounted jib crane has the option of being motorised or manual with a 180° rotation. The wall-mounted jib cranes are suitable for individual use and avoid clutter in the work area. The lifting capacity of this type of jib crane ranges from 150kg to 4 tonnes with a standard reach of up to 8000mm.

To choose the right jib crane for your lifting application, you need to:

Know the environment in which you want to install your jib crane. This will allow you to choose between a fixed jib crane, a mobile jib crane or a wall-mounted jib crane.

Know the load you wish to lift with the crane. The weight will allow you to choose the necessary lifting capacity.

Know the maximum height and reach required to lift the load.

Know the type of jib crane you want : you can choose between an electric jib crane or a manual jib crane.

A design office is at your disposal to meet your lifting needs for your cranes and gantries. The design office will draw up an estimate according to your request. For further information, please contact our customer service.

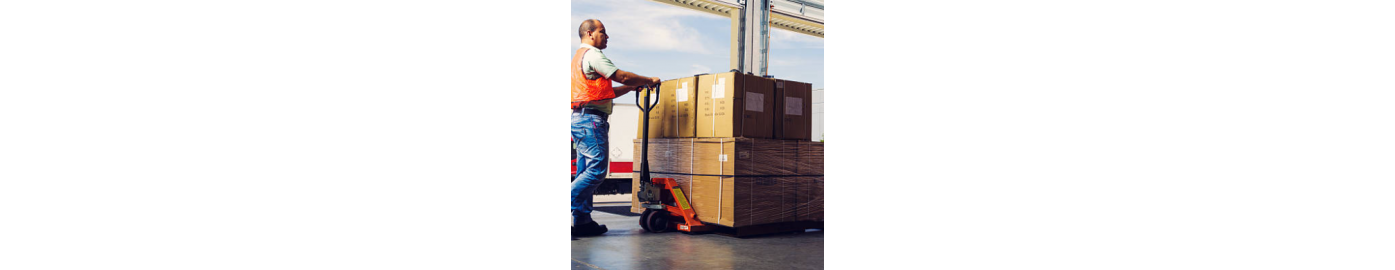

Today, material handling is used by everyone in warehouses, factories or shops. Originally, material handling consisted of moving loads by hand. Today, with the technological advances, industrial companies are investing in more and more efficient handling equipment to improve productivity.

Goods handling is an important operation in the supply chain. Moreover, it requires the use of professional equipment such as forklifts, stackers and pallet trucks. The purpose of these handling devices is to make the task easier and the operation safer for the user.

How do we choose the right material handling equipment for our operation ?

To begin with, there are floor handling machines and dockside handling machines. For floor handling, you can choose a forklift truck that will allow you to move the load from one point to another on a flat surface. For dockside handling, choose hand pallet trucks, electric pallet trucks or stacker trucks to unload the load into the truck.

Your handling equipment should also be adapted to the distance and conditions. For short distance lifting operations, we recommend the use of manual, semi-electric or electric pallet trucks. For medium-distance handling operations, you can use stacking pallet trucks or forklifts. Finally, for handling loads over long distances, forklifts and electric stackers are the most suitable handling equipment.

Finally, when choosing your handling equipment, you must take into account the characteristics of the load during the handling operation, if this is incorrectly assessed it can present a risk during lifting. A load that is too heavy will throw the equipment off balance and put the user at risk.

Next, the environment in which the operation will be carried out must be assessed. The space must be flat and spaced out to place the load. In addition, it is necessary to have a good grip on the load to prevent it from falling. So make sure you choose a machine that is suitable for the space you have available.

All handling equipment must comply with current standards to ensure the safety of loads and users.

What are the tools for materials handling ?

First of all, there is the pallet truck! The pallet truck, also known as a pallet puller, is a truck that can be hydraulic, manual or electric. It is used to move pallets in warehouses, factories or shops. This handling device is practical, easy to use and has a low energy consumption.

Pallet trucks have two forks that can lift a load a few centimetres off the ground. There are three types of pallet trucks:

The manual pallet truck: This is a classic pallet truck that can only be pulled by human effort. The load is lifted by means of a tiller with a handle by manual pumping once the two wheels have been joined. The use of the hand pallet truck does not require any special training. However, appropriate training must be provided to prevent the risks involved in using this machine.

Electric pallet truck: This is an electrically powered machine with the same configuration as a manual pallet truck except that an electrical lifting device is added. The handle bar has the same function as the manual pallet truck but the lifting is done automatically.

The platform pallet truck: This is made with a rear platform as a driving position. On the platform you will find all the electrical controls for the machine, the engine and the steering. The platform pallet truck is driven by battery power.

This machine can only be used on flat, smooth and non-slippery ground. The use of this equipment requires professional training.

If you have any further questions about handling equipment or handling in general, please contact our customer service. They will be happy to answer all your questions.

TRANSPALETTES/DIABLES

TRANSPALETTES/DIABLES  PATINS ROULEURS

PATINS ROULEURS  Diables

Diables  Gerbeurs manuels

Gerbeurs manuels