ROPE SLINGS

How to choose the right wire rope sling?

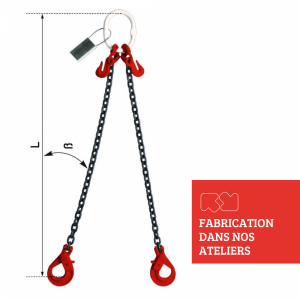

To choose the right wire rope sling for your lifting operation, you need to take several parameters into account:

Start by consulting the load tables for sling types, suspension angles and cable diameters. Based on the table, you can choose the right sling for your load.

The sling you choose should be long and strong enough to support the load.

We recommend that you follow the manufacturers' recommendations for adding lifting accessories.

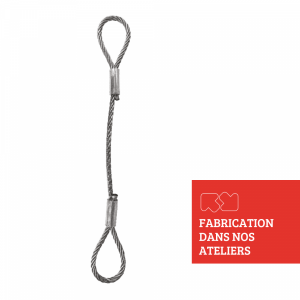

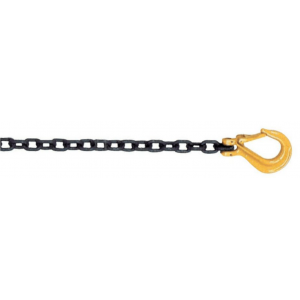

On our Levage Manutention website, you can choose the length, diameter and number of strands for each rope sling depending on the lifting operation. Sleeving of rope slings consists of securing the ends of the strands around the body of the sling. Sleeving can be carried out in our workshops using a press to ensure the robustness of the slings.

There are several types of connections for wire rope slings. The eye splice method is the most popular. This method can only be used for 6-strand slings. The eye splice sleeves are available in stainless steel for stainless steel slings. The loop splice method involves forming a loop and then compressing an aluminium sleeve over two parts of the rope. The strength of the sling depends entirely on the integrity of the pressed sleeve. For rope diameters less than 24 mm, we can use tapered sleeves. For rope diameters of 26 to 28 mm, we can use cylindrical sleeves.

Some of our rope slings come with a small or large aperture lug to increase the strength of the sling. We add standard thimbles. If you wish to customise your thimble, please choose a sling without a thimble and add to your basket the thimble of your choice available in the "Cable sling accessories" section. Then add a comment to your order so that we can assemble your sling with the lug.

Our endless cable slings are also manufactured in our French workshops with over 160 years of experience. Our teams make customised slings according to our customers' requirements. Find out about all the stages in the manufacture of the slings on our social networks (YouTube and LinkedIn).

How to maintain your cable slings?

To maintain your cable slings, we advise you to keep them away from heat and humidity. Remember to carry out a visual inspection before each use of your sling to check its condition. If you notice any damage to your lifting accessory, do not use it. Lifting slings are subject to periodic inspections every year by an expert organisation.

Elingue câble 1 brin

Elingue câble 1 brin