PPE, FALL PROTECTION

Mobile cranes, ideal for indoor use. The mobile jib crane can lift loads ranging from 150 kg to 500 kg with a radius of action of around two metres. The mobile jib crane can be moved by means of all-terrain wheels, which allow it to move on any type of ground. The most commonly used model is the mobile jib crane with a triangular boom with a hollow profile that adapts to workshop conditions.

Drum cranes are the most common cranes, especially in the industrial sector. This type of crane is designed to move very heavy loads of up to several tonnes. They can be used for both indoor and outdoor applications. The jib crane is fixed with chemical anchors or with anchor rods and concrete blocks. The jib cranes are available with a triangular or inverted jib with a rotation range of 270° to 360° and a reach of up to 9 metres.

The wall-mounted jib cranes are equipped with a triangular or inverted jib, which reduces the headroom. The wall-mounted jib crane has the option of being motorised or manual with a 180° rotation. The wall-mounted jib cranes are suitable for individual use and avoid clutter in the work area. The lifting capacity of this type of jib crane ranges from 150kg to 4 tonnes with a standard reach of up to 8000mm.

To choose the right jib crane for your lifting application, you need to:

Know the environment in which you want to install your jib crane. This will allow you to choose between a fixed jib crane, a mobile jib crane or a wall-mounted jib crane.

Know the load you wish to lift with the crane. The weight will allow you to choose the necessary lifting capacity.

Know the maximum height and reach required to lift the load.

Know the type of jib crane you want : you can choose between an electric jib crane or a manual jib crane.

A design office is at your disposal to meet your lifting needs for your cranes and gantries. The design office will draw up an estimate according to your request. For further information, please contact our customer service.

PPE safety definition

Personal protective equipment is a device intended to be worn by a person. The aim is to protect the user against one or more occupational risks that may threaten his health or safety. These risks can be of different kinds. The most common types of equipment are helmets, gloves, shoes, goggles and hearing protection. For work at height, personal protective equipment is mainly safety harnesses, connectors, lanyards and helmets. The performance of the product can be found in the instruction manual provided with the PPE.

The different categories of PPE

Personal protective equipment is divided into three categories, depending on the severity of the risks faced by workers. Category I, for minor risks, for PPE designed to protect against superficial injuries. Category II for major risks, where PPE is intended to protect against mechanical, thermal and chemical risks. And category III for fatal risks, which includes PPE intended to protect against fatal or irreversible health risks. The various PPE intended for protection against falls from a height are included in category three (fall arrest harnesses, lanyards, connectors, anchors).

The differents types of PPE for working at height

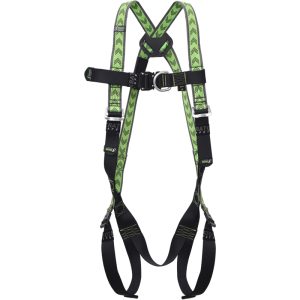

Safety harnesses

The harness is a safety tool, part of the PPE, whose purpose is to protect its user against the risk of falling. It consists of straps and several anchor points and rings. The user can then attach himself to a connecting device.

Fall arrest systems

Fall arresters devices are fall arrest systems that are designed to prevent the person from falling. A fall arrest device consists of an anchorage system, a fall arrest harness and connectors.

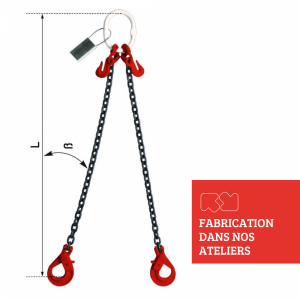

Anchors

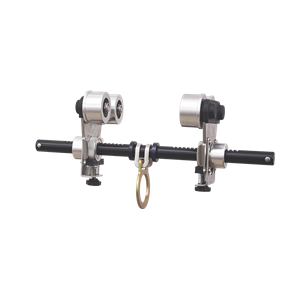

An anchorage is PPE used to connect the fall arrest link to the host structure. There are two categories of anchorage devices: permanent anchorage devices (e.g. lifelines) and temporary/provisional anchorage devices (e.g. steel slings, tripods or textile ties)

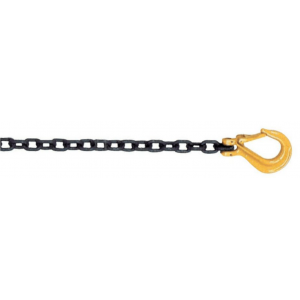

Connectors

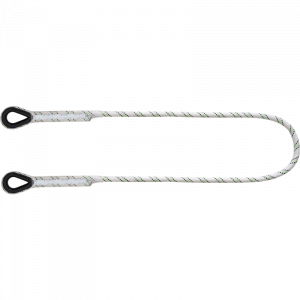

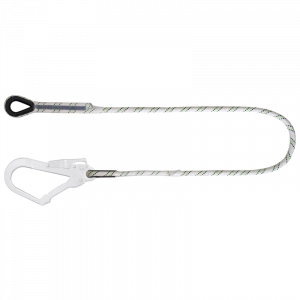

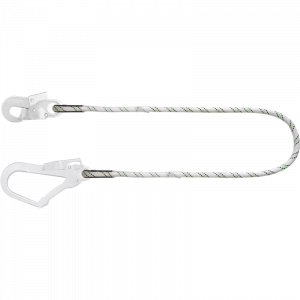

Connectors form a link between the harness and the anchorage point. These include lanyards, abseiling reels and rope sliders.

Helmets

Construction site helmets are essential and indispensable personal protective equipment for all workers in the lifting and handling sector. It is essential PPE to protect the worker's skull.

How to choose the right PPE ?

In order to choose the appropriate PPE, it is important to know that protective equipment differs according to the level of risk and the field of occupation. The choice of PPE is made in several stages.

Risk assessment

The first step is to assess the risks incurred by the worker. To do this, it is necessary to take into account the extent of the risk, the frequency of exposure and the characteristics of the workstation and the performance of the equipment. This assessment makes it possible to define the priority prevention measures that will preserve the health and safety of employees.

Collective protection

Next, it is important to take into account the collective protection in place. This protection is a priority because it makes it possible to reduce individual risks. In some cases or situations, collective protection may be insufficient or impossible to implement. The choice of PPE will therefore depend on the residual risk that could not be reduced or eliminated by collective protection.

In addition to this, it is important to take into account the comfort of the employee, the discomfort that the equipment could cause, the creation of another risk and the compatibility between two PPEs.

PPE regulations

According to Directive 89/566, the employer is required to respect the following obligations concerning PPE :

- Carry out an assessment of the risks incurred by the employee, provide them with suitable and appropriate PPE free of charge.

- Ensure its proper use, operation, maintenance and storage

- Have an annual examination carried out by a third party authorised by the employer.

In the event that PPE is to be used by several people, Article R.233-42 of the Labour Code requires the employer to put in place appropriate measures to ensure that it does not pose any health or hygiene problems for the various users of the product. In addition, the use of second-hand personal protective equipment is regulated, or even prohibited in certain situations.

It is extremely important to keep personal protective equipment in working order. PPE must also be checked periodically, according to the decree of 19 March 1993. This decree imposes a mandatory periodic check for 5 types of protective equipment. We are authorised for all certifications concerning the various PPE.

Finally, users must undergo training which includes, when necessary, training in the use of the PPE in question.

Quality PPE that meets your needs

All our company PPE and site safety PPE products, i.e. harnesses, lanyards, anchor points, fall arresters, connectors, helmets and lifelines, come from our partners KRATOS and NEOFEU. PPE and fall arresters of these two brands meet the European standards currently in force. All personal protective equipment from KRATOS and NEOFEU have the CE mark, proving the conformity of the products. Category III PPE is also marked with the number of the quality control body.

If you need further information about our various products in the PPE and fall protection section, our expert service is available Monday to Friday from 8am to 12pm and from 1.30pm to 5.30pm, except on public holidays, to answer your questions and queries.

You will be pleased to know that all our quotes are free of charge.

Finally, if you would like to obtain information on safety or other subjects related to lifting or handling, we invite you to visit our blog.

HARNESS

HARNESS  LANYARDS AND FALL ARRESTERS

LANYARDS AND FALL ARRESTERS  ANCHORING

ANCHORING  SAFETY CARABINERS

SAFETY CARABINERS  BAGS & HELMETS

BAGS & HELMETS